Q-ton Hot Water Solution

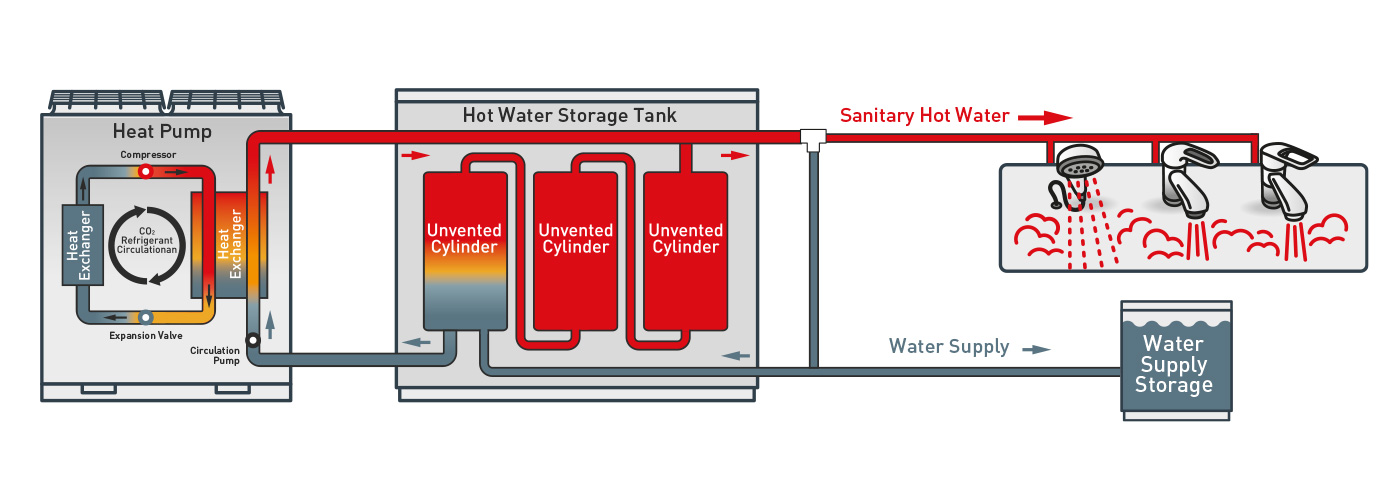

Q-ton is a high efficiency, air-to-water heat pump which utilises CO2 gas to deliver a sanitary grade, hot water & space heating solution for commercial applications such as aged care facilities, hospitals, breweries, wineries, food processing plants, hotels, gyms and more.

POWER: Three Phase | HEATING CAPACITY: 30.0kW

Key features

- Delivers 90°C hot water in as low as -25C ambient temperatures

- Easy to use touch screen control with advanced functions

- Offers massive reductions in both running costs and Co2 emissions

- high quality, robust technology and components

- Much smaller footprint compared to gas boilers

- Modular installation from 30Kw up to 480Kw (1 to 16 units)

What is Q-ton?

Q-ton is an air-to-water heat pump which utilises patented compressor technology and CO2 gas as a refrigerant to offer a reliable and efficient hot water solution for a range of commercial applications. The Q-ton utilises the world’s first two-stage compressor (combining rotary and scroll technology) to maintain high efficiency and significantly high performance, even with cold outside air temperatures.

In addition to offering a sanitary grade hot water solution, the Q-ton can now also be used in variety of space heating applications with return temperatures below 30°C. The new system deign also includes combination mode which allows the unit to deliver hot water supply as well as spacing heating.

Features and Benefits

Q-ton delivers outstanding performance and environmental benefits to a varied number of applications and is exceptionally energy efficient ensuring large reductions in both power consumption and carbon emissions.

COMMERCIAL APPLICATIONS

HOSPITALS

AGED CARE

RESTAURANTS

EDUCATION

MANUFACTURING

GYMS & SPAS

APARTMENTS

OFFICES

HOTELS

BREWERIES & WINERIES

FOOD PROCESSING

Accreditations

The Q-ton is manufactured in our state of the art facility in Japan which a ISO 9001 approved factory developed specifically for the manufacture of high quality and high performance air conditioners and heat pumps.

Easy to use touchscreen control with advanced functions including user friendly scheduling options and one-touch fill up.

Produces 74% than an electric heater and 76% less emissions than a gas boiler.

High coefficient of performance (4.3 in intermediate season) delivering massive reductions in both running costs and CO2 emissions.

Delivers 60°C to 90°C water supply in -25°C ambient temperature. Ability to maintain 100% capacity down to -7°C.

High quality, robust technology and components offering long life expectancy.

Ability to send messages via Modbus communication via the RCI-MDQE interface kit.

Q-ton can be used in variety of space heating applications including underfloor heating and low temp radiators.

Much smaller footprint compared to gas boilers offers easier installation and design flexibility.

| A | B | C | D | |

|---|---|---|---|---|

1 | Model | ESA30EH2-25 | ||

2 | Power source | 3 Phase 380V±5%, 400V±5%, 415V±5%, 50/60Hz | ||

3 | Operation to top up (Intermediate season)*1 | Heating capacity | kW | 30 |

4 | Water amount | L/min | 8.97 | |

5 | Power consumption | kW | 6.98 | |

6 | COP | - | 4.3 | |

7 | Operation to top up (cold season)*2 | Heating capacity | kW | 30 |

8 | Water amount | L/min | 5.06 | |

9 | Power consumption | kW | 10.73 | |

10 | COP | - | 2.8 | |

11 | Operating sound pressure (In intermediate season)*1, 3 | dB(A) | 58 | |

12 | Operating sound power (In intermediate season)*1 | dB(A) | 70 | |

13 | External dimensions (HXWXD) | mm | 1690 x 1350 x 720 + 35 (water pipe connection) | |

14 | Current | Maximum | A | 21 |

15 | Starting | A | 5 | |

16 | Unit weight | kg | Off: 375 During operation: 385 | |

17 | Colour | Sutcco white (4.2Y 7.5/1.1 Approx) | ||

18 | Compressor | Type x Pcs | Hermetic inverter compressor x 1 | |

19 | Nominal output | kW | 6.4 | |

20 | Refrigerant | Type | R744 (CO2) | |

21 | Charged amount | kg | 8.5 | |

22 | Refrigerant Oil | Type | MA68 | |

23 | Charged volume | cc | 1200 | |

24 | Crackcase Heater | W | 20 | |

25 | Anti-freezing heater | For water pipe | W | 21 x 3 |

26 | For drain pan | W | 40 x 2 | |

27 | For drain hose | W | 16 x 3 | |

28 | Heat exchanger, air-side | Type | Copper pipe straight fin type | |

29 | Heat exchanger, water side (gas cooler) | Type | Copper pipe coil, indirect heat exchanger | |

30 | Possession quantity of water | 10 | ||

31 | Fan | Type | Axial flow type (direct coupled motor) x 2 | |

32 | Output x pcs | W | 386 x 2 | |

33 | Air volume | m3/min | 260 | |

34 | External static pressure | Pa | 50 | |

35 | Water pump | Type x output | Non-self-suction spiral type inverter pump × 95W | |

36 | Materials contacting water | PPS | ||

37 | Actual pump head | m (kPa) | 5m (49kPa) @ 17Litre/min | |

38 | Usage temperature range | Outdoor air temperature | °C | -25 to +43 |

39 | Feed water inlet temperature | °C | Top up 5-35, Warm up 35-63 | |

40 | Hot water outlet temperature | °C | 60 - 90 | |

41 | Water pressure range | kPa | 500 or lower (Keep water pressure more than 0kPa at the inlet of heat pump water heater) | |

42 | Defrost | Hot gas type | ||

43 | Vibration and sound proofing devices | Compressor ;placed on anti-vibration rubber and wrapped with sound insulation | ||

44 | Protection devices | High pressure switch over current protection, power transistor overheat protection and anomalous high pressure protection | ||

45 | Pipe connection | Feed water inlet | Rc3/4 (Copper 20A)*4 | |

46 | Hot water outlet | Rc3/4 (Copper 20A)*4 | ||

47 | Drain water outlet | Rc3/4 (Copper 20A)*4 | ||

48 | Design pressure | MPa | High pressure:14.0, Low pressure: 8.5 | |

49 | IP Code | IP24 | ||

50 | 1. Performance of operation to top up during intermediate season shows the capacity measured under the conditions that outdoor temp is 16°C DB/12°C WB, water inlet temp is 17°C and how water outlet temp is 65°C. | |||

51 | 2. Performance of operation to top up in cold region shows the capacity measured under the conditions that outdoor air temperature is -7°C DB/-8°C WB, water inlet temperature is 5°C and hot water outlet temperature is 90°C excluding heater for anti-freezing water (191W). | |||

52 | 3. Operating sound shows a value is measured at 1m in front of the unit and 1m above the floor in an echoic room where the sound is slightly resonated. Accordingly, if the unit is installed on an actual site, it is normal that the measured sound levels may be higher than the value shown above, due to surrounding noise and echo within the room. | |||

53 | 4. Pipe size 20A=DN20=20mm=3/4in. | |||

54 | 5. The actual hot water outlet temp may vary ±3°C from target temp according to the change of outdoor air temp and water inlet temp. If feed water inlet temp is 30°C of high and outdoor air temp is 25°C or higher the water temp may be controlled to ensure temp does not increase too much. | |||

55 | 6. Ensure clean water is used. Water quality should follow the standard which MTH specifies. If the water quality if not up to standard it may cause issues within the unit such as scale build-up and/or corrosion. | |||

56 | 7. These articles mentioned above may vary without notice accordingly to development status. | |||

57 | 8. Electrical installation work must be performed by an electrical installation service provider qualified by a power provider of the country. Electrical installation work must be executed according to the technical standards and other regulations applicable to the electrical installations in the country. | |||